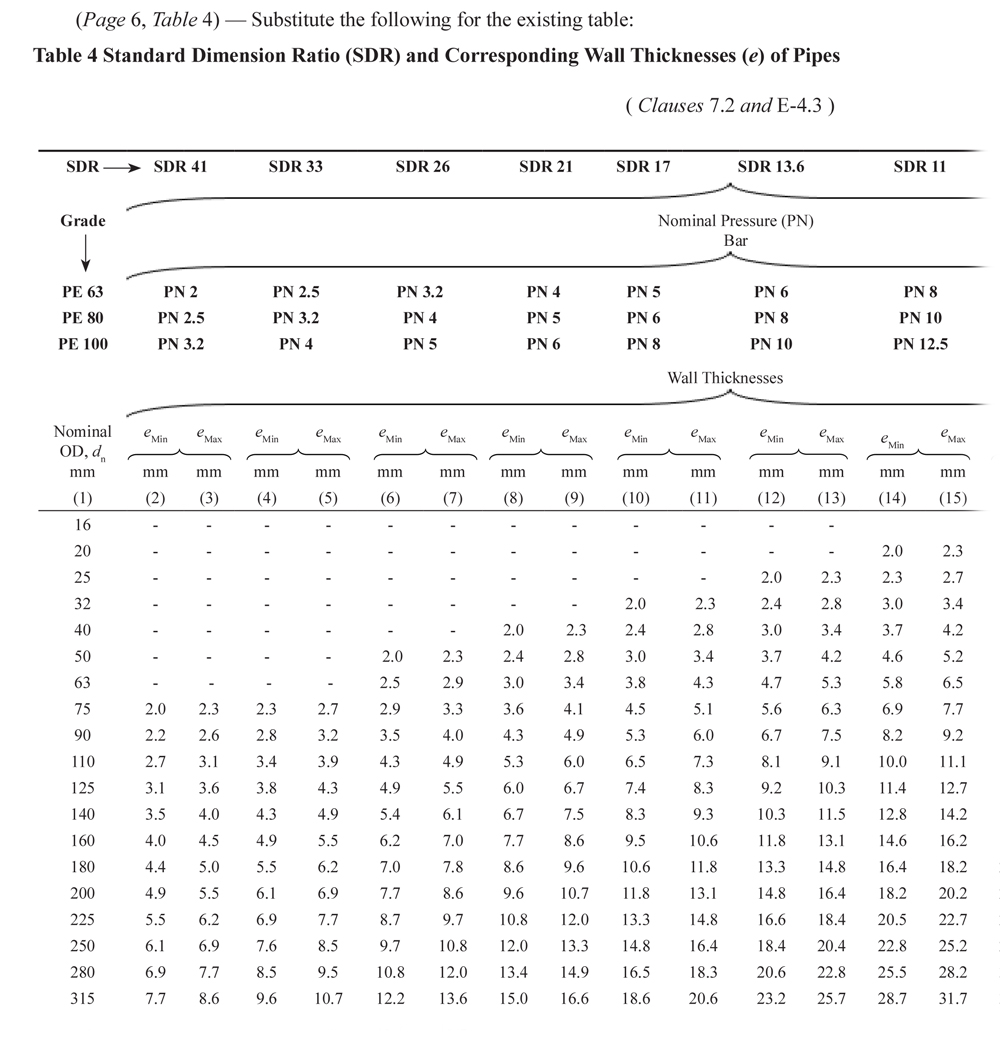

Ganpati Polymers manufactures a wide range of Polyethylene pipes, High Density (HDPE) conforming to BIS Standard. Polyethylene is a thermo plastic polymers consisting of long chains of ethylene or ethane. It is a wax like thermoplastic with density varying from 940.0kg/m³ to 960.0kg/m³ which is less than the density of water. The only two additives that are added to polyethylene are Carbon Black, within the range limit of 2-3% in order to add reinforcement and to increase polyethylene’s weathering properties and trace amounts of anti-oxidant. HDPE is strongly resistant to stress cracking and has low creep rupture properties. It has excellent insulation properties over a wide range of frequencies and is not chemically active. HDPE pipes are one of the two largest thermoplastic pipelines available and by far the most versatile. The Pipes & Fittings are offered in PE 63, PE 80 and PE 100 grades, compliance to IS-4984 .